The challenge in manufacturing modern batteries is to maximize their energy density, reduce their manufacturing costs and extend their useful life. To achieve this, sensors from Micro-Epsilon are used throughout the entire manufacturing process. They not only perform various measurement tasks for machine monitoring and quality assurance, but also thickness control of strip material as well as coated films. Both electromagnetic and optical sensors can be used for these measurement tasks.

Inline testing in battery production makes a significant contribution to increasing economic efficiency, conserving resources and quality assurance. To achieve this, high-precision sensors from Micro-Epsilon are used in every stage of production from electrode manufacturing to assembly and forming. The company’s extensive and diverse product portfolio offers the right measurement method with the right sensor for every type of coating and all measuring objects. A central measurement task is the precise thickness measurement of battery film and the film coating. This is possible using both electromagnetic and optical sensors.

Strip and coating thickness measurement with electromagnetic sensors

With double-sided thickness measurements, two sensors are arranged opposite each other and measure the distance to the film. Depending on the type of sensor used, this arrangement achieves an extremely high resolution.

Electromagnetic sensors from Micro-Epsilon offer numerous advantages in thickness measurement. Thanks to integrated temperature compensation, they deliver stable measurement values in the submicrometer range and are also used in drying processes. Capacitive sensors are often used for thickness measurement of strip materials and coatings. These are mounted opposite each other and measure from both sides on electrically conductive materials. The linear distance signals of both sensors are calculated in the controller and converted to a thickness value. Compared to optical methods, the measurement spot is larger. This allows averaging of structures and irregularities. In addition, capacitive sensors can also be used at high temperatures and fluctuating temperatures, which often poses major challenges for other measurement methods. Using the capaNCDT multi-channel controllers enables processing of the values of several sensor pairs using just one controller.

Capacitive sensors are often used for applications which require highest precision and stability with a resolution down to the submicrometer. Thanks to their innovative technology, capacitive sensors from Micro-Epsilon provide highly accurate readings even in harsh industrial environments. They provide measurement values down to the sub-micrometer range even at high temperatures and are also suitable for dusty industrial environments. Capacitive sensors from Micro-Epsilon also provide long-term stability as there are no integrated components that could reduce the service life. Another strength is the combination variety. Each capacitive sensor can be operated with any Micro-Epsilon controller without calibration, which is particularly advantageous when replacing components.

Coating thickness measurement with optical sensors

In addition to confocal chromatic sensors, white light interferometers are particularly well suited to thickness measurement and provide high precision results. They are typically used to monitor and control wet coating processes, but are also suitable for dry processes.

When highly accurate measurement results are required, optical measurement methods are indispensable. Confocal chromatic sensors and the high-precision interferometers from Micro-Epsilon work on the basis of white light technology. Both measuring systems are used for distance and thickness measurement in areas where the highest accuracy and signal stability are required.

The optical sensors are mounted opposite the material and perform precise measurements of coated and uncoated films. They operate at high resolution and can be used in both wet and dry coating processes. Due to the small light spot diameters, even the smallest detail on the film surface can be reliably detected. In addition to confocal chromatic sensors, white light interferometers are also ideal for high-precision thickness measurement.

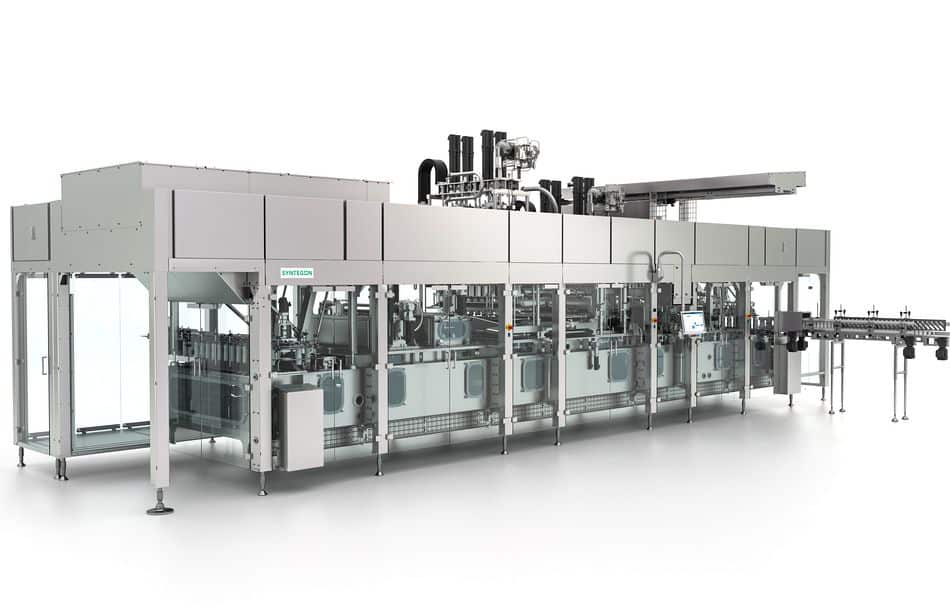

Turnkey system for thickness measurement of electrode coating

ThicknessGAUGE sensor systems are used to measure the thickness of strip materials in-line. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces. The system uses two optical or electromagnetic distance sensors to detect the strip thickness. The sensors are perfectly aligned to each other and calibrated. Furthermore, thickness calibration at the factory ensures high precision. By means of a linear axis, the ThicknessGAUGE sensor systems can be moved to measure the thickness across the entire strip width.

In environments with dirt and high temperatures, the ThicknessGAUGE O.EC system is used. It uses the innovative combiSENSOR. This includes an eddy current sensor that measures onto the guide roller and a capacitive sensor for distance measurement onto the material surface. The exact thickness value of the electrode coating is obtained from the signal difference.

Wet film thickness measurement of the anode and cathode material

In the coating process, the film is coated either continuously or intermittently and over a width of up to 1000 mm. Important factors are the film and coating thickness, surface quality, cleanliness and avoidance of gas inclusions. To monitor the wet film thickness of the anode and cathode materials, an accuracy of <±1 μm is required at 150 to 500 µm object thickness.

The ThicknessGAUGE sensor systems combine high-precision sensors with a coordinated mechanical system including a traversing axis. Thanks to a comprehensive software and interface package, the sensor systems can be integrated into production lines in a process-safe manner.

For this measurement task, it is recommended to use the ThicknessGAUGE, an inline measuring system consisting of a linear unit with electromechanical drive, two confocal chromatic distance sensors, an automatic calibration unit and a multi-touch IPC. The confocal sensors measure the material surface from two sides using the differential method. Based on automatic calibration with a reference target, the distance between the two sensors is determined at regular intervals. In measuring mode, the two sensors each detect the distance to the material surface. The material thickness is calculated from the known distance between the two sensors and the distance values. Thanks to the high resolution of the confocal sensors, they reliably detect even the slightest deviations.

The high precision of ±0.25 µm and the measuring rate of up to 5 kHz enable fully automated thickness measurement. Using the linear axis to move the ThicknessGAUGE over the strip allows the complete transverse profile to be determined.

Conclusion

The use of Micro-Epsilon sensors in battery production increases economic efficiency and quality. Micro-Epsilon develops, produces and distributes a globally unique range of sensors, measurement systems and customer-specific solutions. Both sensor and system expertise are offered from a single source. The wide product range, which is based on different measuring principles, is ideal for monitoring production processes in battery cell manufacturing. Various measuring methods are available for measuring the thickness of the battery film, which are optimized for the respective process steps.

Author: Dipl.-Ing.(FH) Franz Hochwimmer, Consulting & Sales for Measuring & Inspection Systems, MICRO-EPSILON MESSTECHNIK GmbH & Co. KG, Ortenburg/Germany

Source: Micro-Epsilon