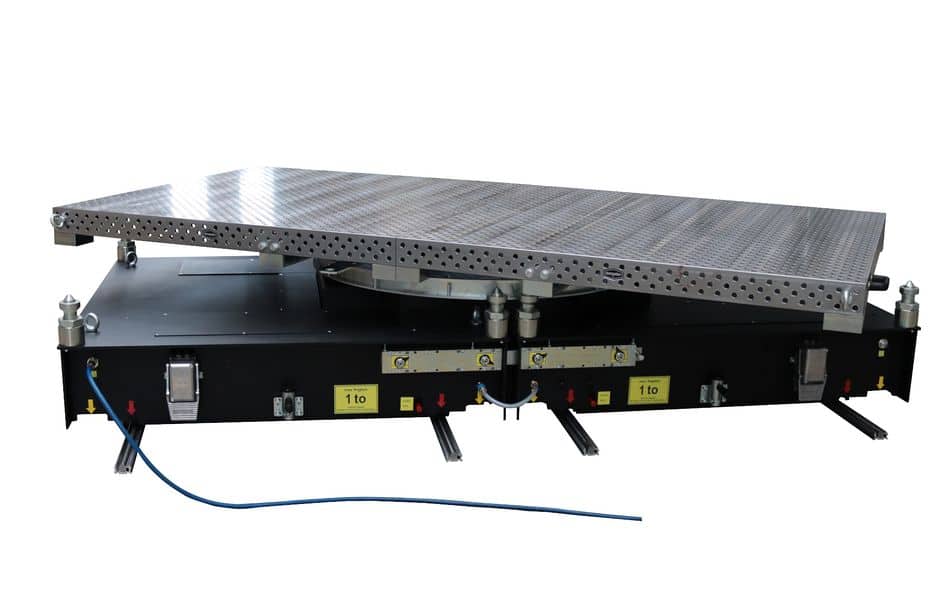

The intra-logistics specialist Losyco has expanded its LOXrail system, adding a new automatic trolley with a rotating loading platform for flexible orientation of heavy workpieces directly on rails.

This solution, which has already been successfully implemented in a machine factory, increases flexibility in assembly line layouts and simplifies the adaptation of the rail transport system to existing production lines and floor plans. The new trolley can be realized in different dimensions according to customer requirements. It enables manual or motor-driven rotation and orientation of payloads up to 10 t. Application areas include laser and robot welding cells, measuring machines, feeding systems and other production systems requiring highly precise positioning and easy access to workpieces. The turntables can be powered via drives installed at the respective work stations or onboard drives fed via cable, energy guiding chain, battery or induction. Losyco is thus expanding its adaptable range of LOXrail-based transport systems for production logistics, material flow and machine loading and unloading, which ranges from manually moved trolleys to shuttles and transport platforms with sensor-controlled automatic braking to versions with mechanical or semi-automatic steering.

Source: Losyco