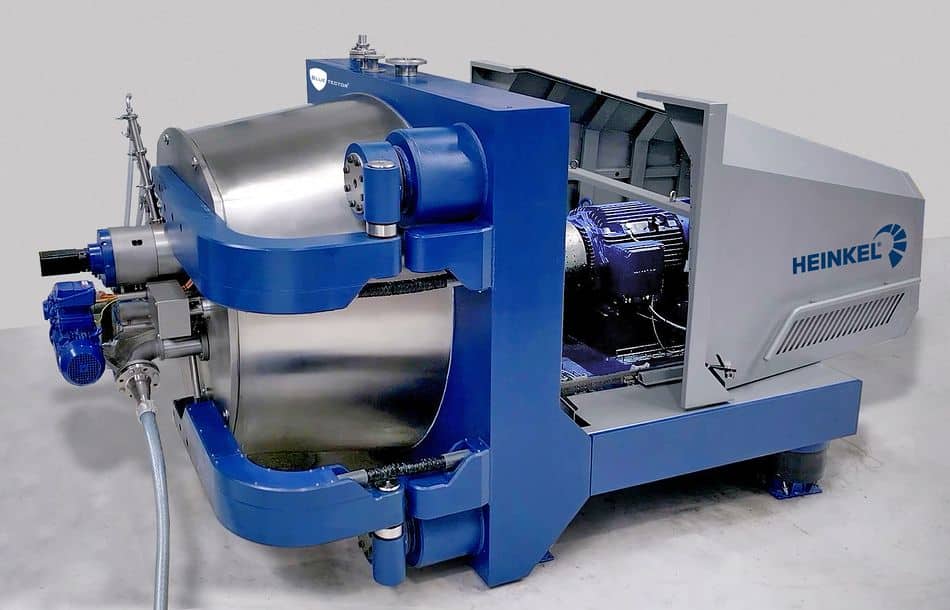

For the first time, the centrifuge specialist Heinkel will be presenting its newly developed Bluetector horizontal peeler centrifuge in size 1250 live at Achema 2024 in Frankfurt am Main. From 10 to 14 June 2024, the industry specialist will be showcasing its product innovation with patented housing design, all-electric, hydraulic oil-free drive concepts at stand C49 in hall 6.0. The highly flexible centrifuge is therefore ideal for efficient manufacturing processes in 24/7 mono-production as well as for operation as a multi-purpose system.

Achema is the leading trade show for the process industry with a global signal effect for the chemical, pharmaceutical, biotechnology, energy and environmental sectors. At the joint booth C49 in hall 6.0, the Heinkel Drying and Separation Group with its brands Bolz-Summix, Comber, Heinkel and Jongia will be presenting innovative product highlights and tried-and-tested solutions. The group is one of the few solution providers of systems for filtration, centrifugation, mixing, agitating and drying. The expertise of the corporate group enables effective process solutions – from laboratory devices to complex production facilities.

Reliable multi-purpose operation due to innovative discharge process

With decades of experience, Heinkel is one of the leading manufacturers of peeler centrifuges, classifying centrifuges and inverting filter centrifuges in the chemical, fine chemical, pharmaceutical and food industries. At Achema 2024, the industry specialist will be presenting its new Bluetector horizontal peeler centrifuge.

This product innovation not only provides excellent product quality at high production volumes in continuous operation, but is also ideally suited as a multi-purpose system. The new peeler ensures low-shear and gentle product discharge, offering maximum flexibility for the discharge process, as the parameters can be variably adjusted depending on the product and process requirements. This refers both to the variability between different recipes and within a recipe. Thanks to the intuitive user interface, the operator can adapt the parameters in real-time. It is easy to realise sampling and batch subdivision, e.g. for barrel filling. The design of the peeler also protects the discharge screw from contamination, which in turn supports the high product quality.

The hydraulic oil-free, all-electric discharge process, which includes removal and emptying, not only ensures low energy consumption, but also provides a hygienic process environment. The integrated, fully automatic cleaning system (CIP) minimises cycle times and ensures productivity and product quality in the same way.

Innovative drive concepts for eco-friendly and clean processes

With the new Bluetector peeler centrifuge, energy savings of approximately 50,000 kWh per year can be realised due to the innovative drive concepts – even in hazardous areas up to ATEX zone 1. The elimination of hydraulic oil and drive belts means optimised cleanliness and ease of maintenance. A slidable machine cover protects the technical areas of the machine, facilitates maintenance work, reduces noise emissions and ensures a safe working environment for the machine operator.

Bluetector multiple award-winner

The Bluetector peeler centrifuge received confirmation of its professional and sophisticated design with the “Special Mention” award at the renowned international Baden-Württemberg “Focus Open” design competition and also made it to the final of the “Best of Industry Award” 2023, category “Process Industry”. The patented and optimised housing shape permits efficient filtrate drainage through the rear wall without any additional guidance for the liquid. When flooding, up to 35 per cent less cleaning fluid and correspondingly less filling time is required due to the shape of the housing, which results in reduced batch times.