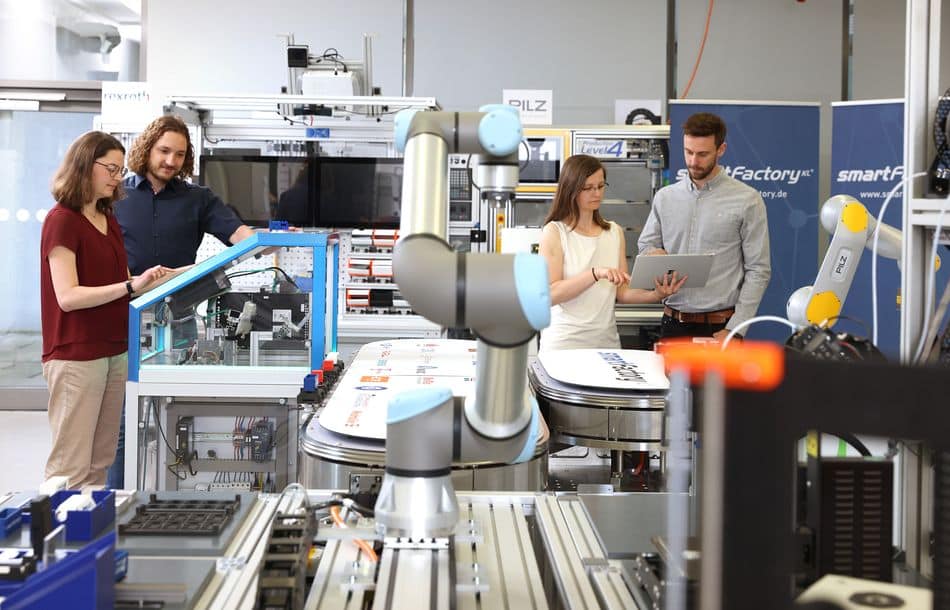

Germany’s Plattform Industrie 4.0 presents a groundbreaking document with the Manufacturing-X Whitepaper. Since 2019, the ecosystem being built by SmartFactory-KL has been based on the vision of Production Level 4 (PL4) and the core concepts are already partially implemented: resilience, sustainability, flexibility, digital twins, interoperability, skills-based production architecture, and shared production.

Manufacturing-X (M-X) is taking the initiative in addressing what the production of the future should look like in Germany. One concrete result of Industrie 4.0 was the administrative shell, which is now being further developed into the Digital Product Pass at SmartFactory-KL (SF-KL). The complete digital mapping of the products makes possible what M-X calls: resilient manufacturing – conceived for a closed loop economy, sustainable and energy efficient, while able to withstand external influences and reduce CO2 emissions. Artificial intelligence can control and coordinate secure trade via digital platforms, with the goal of strengthening competition.

SF-KL is also working on another key enabling technology called functional safety, without which modular manufacturing would fail. “If we don’t plan safety concepts from the beginning, their absence becomes a showstopper,” said Prof. Prof. Martin Ruskowski, chairman of the management board of SmartFactory-KL. “One of our main areas of study is operational safety inteligence where we are finding ways to combine AI methods with classic safety requirements. Such intelligent safety concepts (only in german) work with knowledge graphs and digital twins.” The aim is to protect people and machines from harm. This does not always demand stopping the entire production process. Flexible response patterns that can adequately adapt to the situation are much more practical.

Source: Smartfactory-KL