In a new strategic partnership, Sumitomo (SHI) Demag has announced its cooperation with Fraunhofer Institute for Production Systems and Design Technology IPK in Berlin. The aim of this strategic partnership is to develop an economical inline inspection process that achieves 100% control of micro and precision injection moulded parts in the shortest possible cycle time.

For any fully automated high-precision plastic production line, quality control is critical. Yet, achieving this level of precision can also cause production, machine, automation and tooling bottlenecks. Producing optical plastic injection moulded components in particular typically encounters inefficiencies as a result of performing continuous checks. In turn impacting the entire output through significant loss of cycle time.

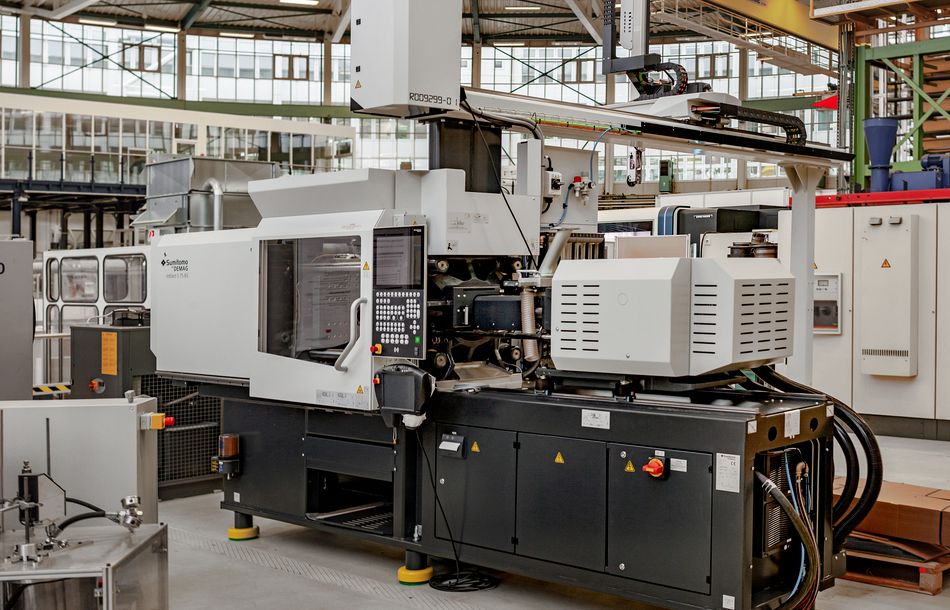

In support of this research initiative, Sumitomo (SHI) Demag is supplying Fraunhofer IPK with a fully electric, high-speed injection moulding machine IntElect S, equipped with automation and a conveyor belt. The company’s Speed series of all-electric machines, currently available with clamping forces of 50 to 180 ton, is designed specifically for high-speed applications with short cycle times of less than 5 seconds. Deployed widely in the medical technology and electronics industries, as well as in other markets requiring high precision, the high-speed series complements the institutions’ investigative research and development program.

Source: Sumitomo (SHI) Demag