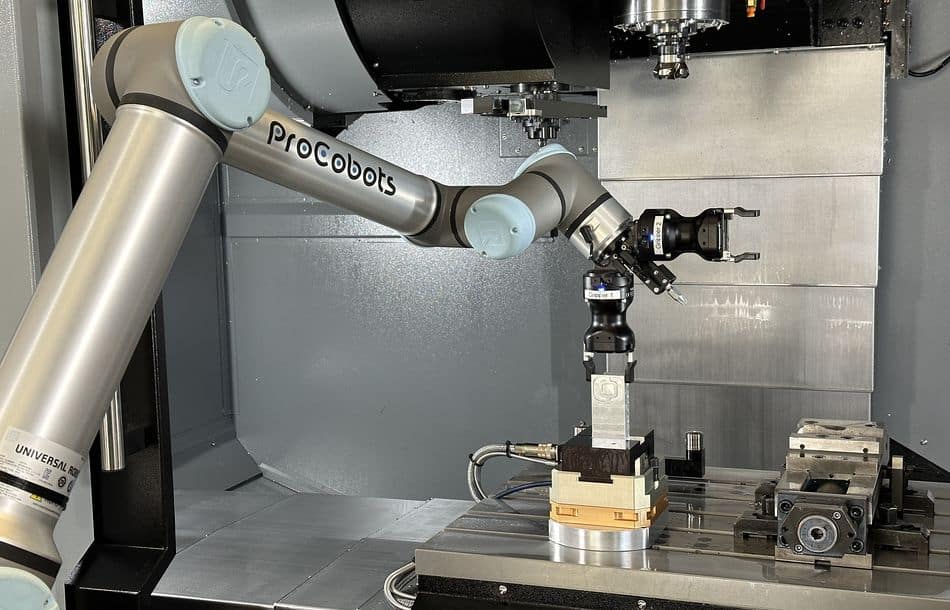

In order to achieve clean end products, sharp edges, unevenness or overhang must be reliably removed during metal cutting and casting processes. To automate the deburring process Schunk has expanded its portfolio for robotic material removal.

The Schunk robots can be used for automated deburring. Deburring of the workpieces can be carried out concurrently with the machining operation of the next workpiece, thus saving an additional work step. With robots assigned to dirty, monotonous tasks, the employees who work alongside them will benefit from more safety and better ergonomics.

With the CRT, RCV, and CDB, Schunk has developed three units for different deburring tasks providing an optimal tool for any application. The pneumatically driven file, CRT, is particularly suitable for small and narrow tool geometries. The pneumatic RCV deburring spindle proves its capabilities during cleaning of blanks and milled parts. Since different rotating tools can be used, the RCV can be flexibly used for various deburring tasks. The CDB unit also facilitates the changeover from manual to automatic processes. For the first time, proven hand-guided deburring blades can be used.

Source: Schunk