Sustainability is more than just a trend. In fact, in today’s business world, a sustainable approach is an absolute must for all modern enterprises. The issue is a particularly important focal point in the mechanical engineering sector, where energy use and efficiency have a considerable impact on a company’s ecological footprint. Innovative solutions that combine economic efficiency with energy efficiency and environmental compatibility are therefore in high demand.

Switching to more modern processes and technologies and new ways of thinking is essential for increasing efficiency and reducing energy consumption – and thus for improving a company’s ability to compete. The targeted exchange and pooling of knowledge between companies creates new perspectives and room for innovation.

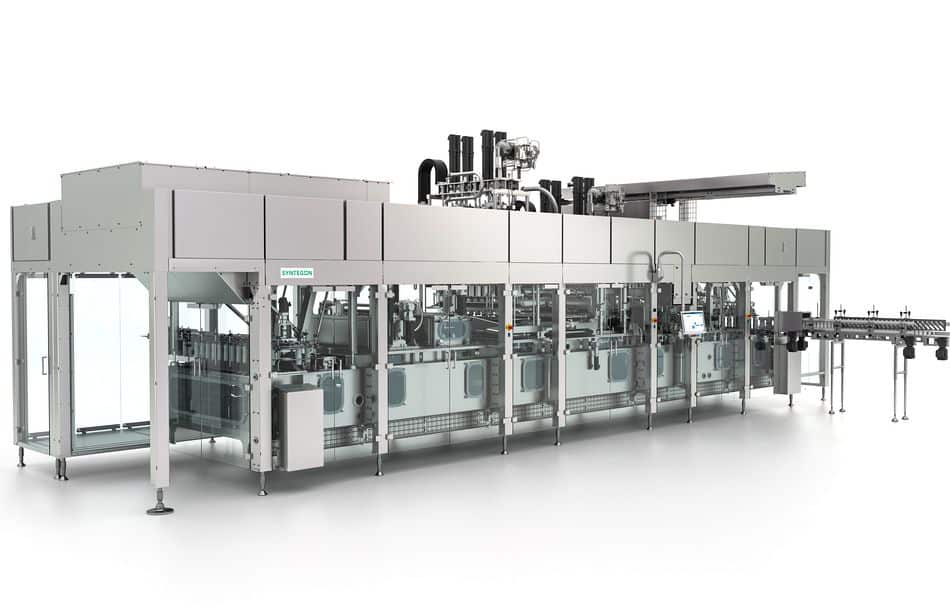

The partnership between two family businesses – Sew‑Eurodrive and Hugo Beck – is a prime example of how innovation can be combined with a sustainable mindset in the mechanical engineering sector. The aim of the collaboration was to reduce the energy consumption and, therefore, the carbon footprint of a horizontal form, fill, and seal (FFS) machine. The result is the flowpack X packaging machine, which is fully equipped with automation technology and drive components from Sew‑Eurodrive. This horizontal FFS machine is proof that a sustainable approach in packaging technology can also yield major economic benefits – and that a change in thinking pays off.

The aim of the project was to replace traditional pneumatics with state-of-the-art electromechanical drive technology – and thus to save energy and cut costs. Thanks to StarterSET 616 and the Sew‑Eurodrive extensions, it was possible not only to replace the pneumatic system of the horizontal FFS machine, but also to cut the overall energy consumption by 23 percent. What’s more, maintenance costs and carbon footprint were reduced substantially, too.