B&R now makes it easier to implement safety communication between machines and machine modules. An update to its mapp Safety software now enables programmable safety functions to be used across complex manufacturing systems with virtually no additional effort –reducing the time spent implementing systemwide safety functions.

The software components in B&R’s mapp Safety package improve communication between safety controllers and simplify safety applications. New system components can be added at any time without having to rewrite the safety application. To put a new component into operation, all the operator needs to do is adjust a few parameters on the HMI screen.

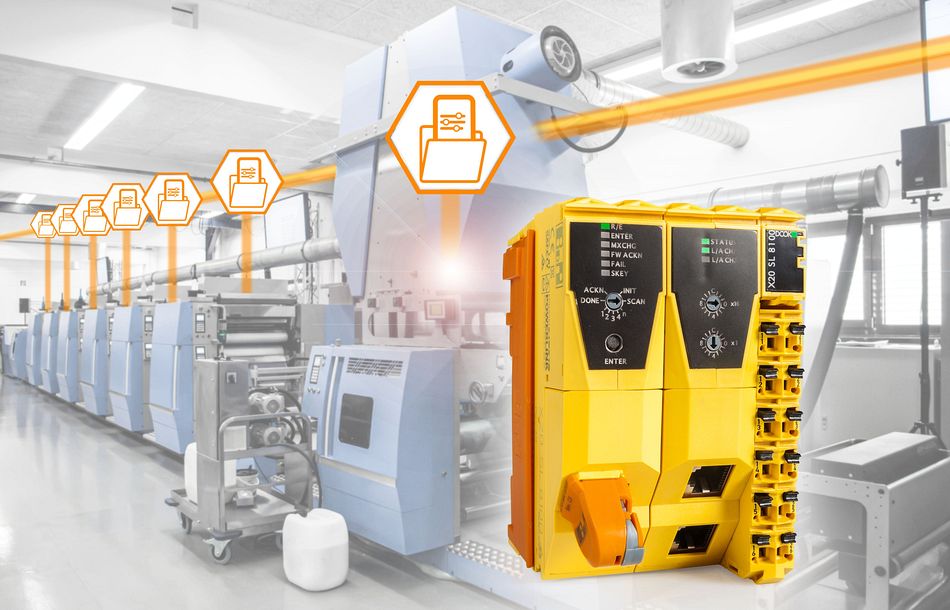

With B&R safety controllers, users can configure up to 150 communication connections to other safety controllers. Even the compact SafeLogic-X controllers support these functions and can be incorporated in machine-to-machine networks.

Data is transmitted using the OpenSafety protocol via Powerlink or UDP. Any proven cable or wireless technology can be used as the transmission media.

Source: B&R Industrial Automation