To conserve resources and reduce operating costs, the service life of oils in hydraulic and lubrication systems should be maximized. In addition to system-compatible filtration with the aim of stabilizing the cleanliness class, this includes permanent monitoring of various parameters by means of sensors such as the CM series from Bühler Technologies in Ratingen, Germany. These sensors continuously monitor the temperature, conductivity, and permittivity of the oil. From these values, the aging of the oil and thus the remaining service life can be derived. Why this effort?

In lubrication technology in particular, the oil has the status of a design element and must exhibit certain properties over its service life in order to ensure the safe operation of the overall system. The desired properties are created by additivating a base oil. The additives will change as a result of tribological stresses in the course of operation, as well as external stresses such as humidity or air pollution, and the oil will ‘wear out’. To enable the sensors mentioned above to perform their task in a targeted manner, they ‘familiarize’ themselves with the values of the fresh oil, so to speak, in a teach-in phase. The on-board algorithms then calculate the probable service life of the oil from the recorded values and set corresponding limit values. If the correlation of the parameters to each other changes in the course of operation, this influences the remaining service life and the CM sensor resets the limit values.

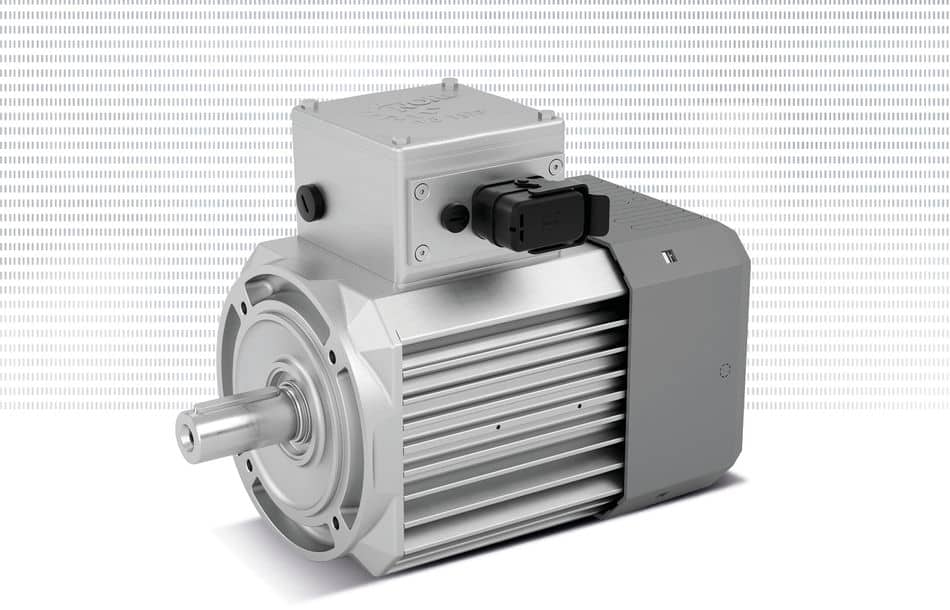

Source: Bühler Technologies