Anything can be consolidated: finances, political positions, companies, supposedly even marriages. But engineering? That especially! Consolidating means “bringing together several parts to form a whole” or put simply: unifying, strengthening or securing. And just as a strong rope is created from many individual strands, so too can engineering be consolidated by bringing together the various planning disciplines and tools in plant construction. Result: one source, one authoring system, significantly reduced interfaces, no waiting times and transmission errors saving a lot of all that. Especially engineering, procurement and construction contractors (EPC), faced daily with an enormous variety of tools and suppliers, know how valuable consistent data is.

It starts with EPCs having to juggle different sources of information: descriptive texts, e.g. on required standards or legal frameworks, capacity specifications, documentation requirements and much more. The Excel files, PDFs, DOCxs are then collected as files, in folders, document management systems or similar – depending on the client, highly variable in quality and detail. But in this state the information is only archived, it does not usually fit together, let alone go on to be directly editable.

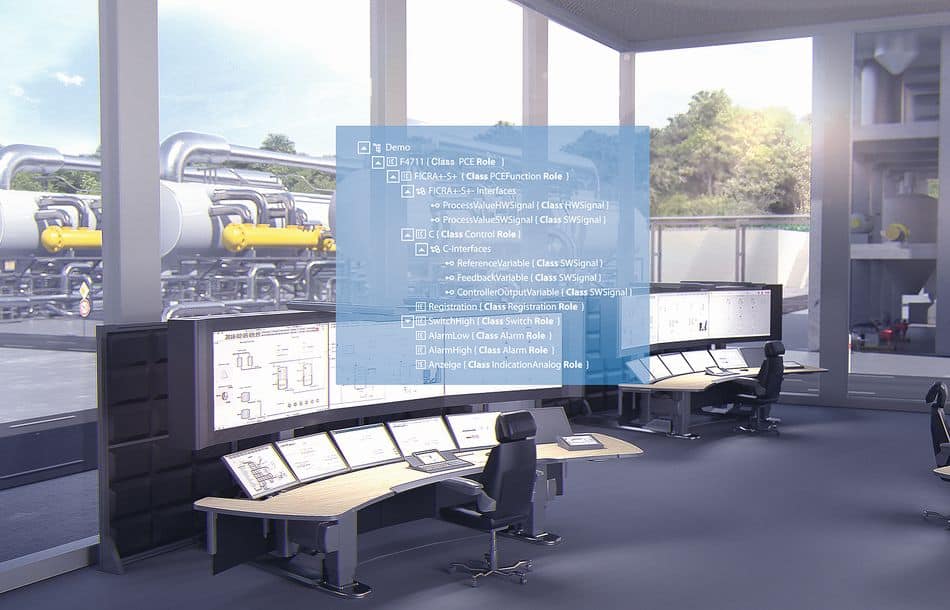

The diversity cannot be changed, but the usability of the data can, however. This is why engineering software expert Aucotec developed the cooperation platform Engineering Base (EB). All the different information can flow into this platform right from the start – whether labelling lists, specifications for ambient pressure, named devices, templates, standards or functional structures – all this data can be created as objects in EB without even having to create a single document. In this way, engineers can build up the desired plant structure right from the start. In this way, they consolidate the diverse input strictly digital, and the original documents no longer need to be consulted.

Consistent by nature

EB itself then consolidates all inputs as an authoring system virtually by itself. Since the platform is THE single source of truth (SSoT) for all parties involved – from the initial concept to process design and detail engineering with instrumentation and wiring to the function charts for automation and configuration of the control system modules – it cannot do otherwise. Once the structure has been created according to the specifications, anyone making further entries follows it automatically. If PFDs and P&IDs are developed in different tools, they are never based on the same data, even if the tools come from the same manufacturer. Not so in EB. The active consolidation of engineering disciplines is simply not necessary. Everything that the PFD experts have contributed is at the same time the basis and available for elaboration by the P&ID professionals and so on. This creates effortless consistency incidentally, a particular advantage for EPCs. The usual synchronizing and data transfer as well as the associated errors are saved by EB as SSoT “by nature”.

But uniting engineering disciplines in a central data model is only part of Aucotec’s consolidation principle. This is because there are still numerous supplementary systems with data relevant for engineering, such as ERP, simulation tools, 3D or the control systems.

Seamlessly from scenario to engineering

In many cases, simulation is one of the tasks of EPCs. Almost every chemical process has its own tool. Some are available on the market, many are developed by the clients themselves. In the case of large plants, certain sections are simulated module by module. First one mass flow, then the adjacent one. Different constellations result in a corresponding number of scenarios. In order to compare them, experts usually place XLS tables next to each other and sort through them. The scenarios finally selected must then be transmitted to the engineering system in order to pass the results on from there to calculation tools for further calculations as a direct transmission from simulation to calculation is not possible.

EB saves transferring and sorting. The simulation results can be automatically imported into EB and consolidated, for example, into continuous flowstreams. In addition, the platform automatically compares the imported scenarios. It shows all the differences in an instant, without the hassle of jumping back and forth between Excel spreadsheets and without the risk of missing anything. Another plus: the finally selected scenarios are already in EB and are thus the basis for seamless further editing by the engineering specialists or for passing on to a calculation tool. If a parameter changes, a new simulation is quickly compared and incorporated into a new calculation. Even the experts who have already started an object specification can see immediately if there have been any changes. All integrations and comparisons take place in EB’s data model, which has central access to the entire plant knowledge, including the engineering-relevant information from 3D, ERP and automation.

In EB’s SSoT, the editors keep enhancing the model according to the given structure until a comprehensive, consistent digital twin has been created, which not only serves as the origin of the plant to be built, but also as an easily updated image of the finished physical plant.

Neutral data hub

No matter how many simulation tools, phases and scenarios, how many calculations, which 3D tools, ERP or control systems are in use, EB “can work with any of them”, also thanks to its communication standard EBML. When consolidating the various external data, the platform also merges, for example, different terminology for the same object into a neutral designation or transforms different units of measurement from the tools into a generally understandable unit. Users do not need to know how the various systems work and do not have to worry about anything, EB ensures consistency.

In addition to the many complementary tools, EPCs also have to deal with a wide variety of suppliers. Their data must also be integrated and consolidated. Before that, however, the suppliers need a specific brief, for example to obtain tenders or approvals. If an EPC wants to send a hardware request to different manufacturers, he pulls all the relevant specifications from EB’s central model into an intelligent data sheet. Searching and collating this data from various discipline-specific tools is a thing of the past. Suppliers complete the sheet according to their capabilities; the changes are immediately identifiable from the automated revision of the datasheets. With a document management system, the tender could at best be “filed” as a document, but in EB the data itself ends up there, directly reusable.

EB also passes on its neutral data to other systems, for example for calculations or control system (DCS) configuration. In addition, the platform can output signal assignment lists or “feed” a predictive maintenance system with the information that enables it to correctly interpret the signals from the running plant.

Consolidation therefore has many aspects, but always one result: an enormous gain in consistency and time from numerous synergies – because everyone is pulling in the same direction.

Author: Reinhard Knapp, Head of Global Strategies at Aucotec AG

Source: Aucotec