To deliver flexibility, robots frequently need to use multiple different grippers, which is why fast and reliable tool-change technology is paramount. However, many solutions are expensive and carry some risk due to complex air/signal connections.

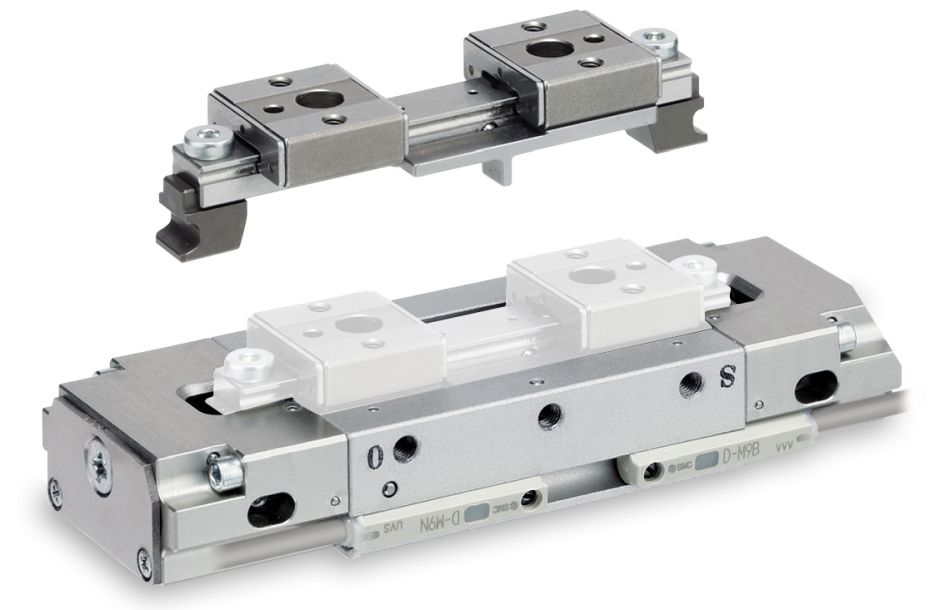

For this reason, the team of design engineers at SMC developed the MHF2-X7076A, a modular, low-profile air gripper with finger-change function. This automatic tool-change device for robots means users simply replace the end of the gripper (the finger) without any risk. The wiring and piping are bundled together in the body of the air gripper (robot side) to improve electrical contact during tool changes and reduce air leakage.

In addition, the company offers wireless communication with the gripper to eliminate any risk of communication loss and stoppages. The EX600-W wireless system means less cables and connectors, reduced installation and maintenance, and fewer breakages and disconnections to deliver reliable, noise-resistant communication. According to SMC, robot users are increasingly adopting the fast-response EX600-W wireless system improve their OEE (overall equipment effectiveness), a key metric for any production or process operations.

Source: SMC