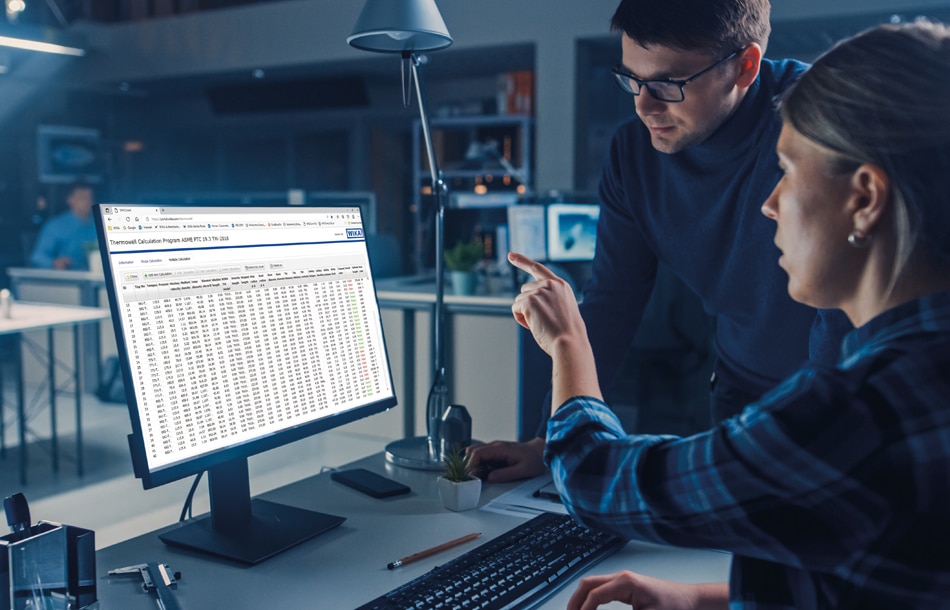

Plant manufacturers preparing to install temperature measuring points often face the dilemma of how to design the thermometer thermowell or protection tube. Wika’s wake frequency calculation software, which conforms to ASME PTC 19.3 TW-2016, provides an answer. This proven software is now available in a web version (V3.0).

As Voltaire rightly said more than 300 years ago, perfect is the enemy of good. For more than 20 years now, Wika has been using its own Excel software based on VBA macros to calculate a thermowell’s wake frequency. Several thousand users worldwide have faith in the tool’s abilities. The software’s functionality has been improved with each new version and adapted to changes in the underlying standard. Furthermore, flow tests have confirmed that the calculation produces accurate results.

Nevertheless, experience in recent years has shown that the traditional VBA-based software is no longer the ideal it once was. On the one hand, newer Windows versions have increasingly created problems while on the other, a growing number of companies are cutting down on the use of VBA-based third-party software for security reasons. In short, the time was ripe for an update.

It was decided to develop an online solution capable of implementing the tried-and-tested functionalities of the Excel version. The new software is easy to understand and self-explanatory, with a clear-cut front end integrating all essential features. Users can choose between two alternatives: a freely available but limited version for calculating a single thermowell or the full version, which requires prior registration and enables simultaneous calculation of any number of thermowells.

Single calculation

This is a fully featured version for calculating a single thermowell according to ASME PTC 19.3 TW-2016. Only a limited choice of materials is available, however. After entering the required process and thermowell data, all the most important results are output in the front end. The information displayed is exactly the same as in the old Excel version. The dynamic results comprise the frequency ratio as well as the safety factor for flexural fatigue stress while the static results are the safety factors for bending stress and the pressure load on the thermowell.

The selected thermowell design is shown in a 3D graphic together with all dimensions needed for the calculation. If required, the calculation and all details can be documented with the aid of the PDF export function.

Multiple calculation

The full version of the software is likewise available to users free of charge following registration and verification. The algorithm is the same as for single calculations. The difference is that the data for any number of thermowells can be automatically imported using the normal Windows copy & paste function. All information on the thermowells and allocated processes must be prepared upfront in a separate Excel list, to ensure that the input parameters are complete and the correct sequence observed. This list can be saved under a freely assignable name and accessed again at any time, for instance in case of modifications.

The calculation is carried out automatically when the data is uploaded. All inputs and their results are then shown in a well-arranged table. Further details such as the Strouhal number, the Strouhal and installation frequencies, the maximum permissible pressure load and the Scruton and Reynolds numbers can also be displayed as an option.

It goes without saying that a PDF for each calculated thermowell can also be generated for documentation purposes with the multiple calculation version or the entire table exported to Excel in order to store the data locally.

Data security

For reasons of data security, the login for a multiple calculation takes place via the proven Microsoft platform Azure Active Directory B2C. Wika has absolutely no way of knowing the user’s password with this solution. A verification code is sent by email each time a user logs in, so that only the person who also has access to the registered email account can actually see and edit the stored calculation data.

Programme features

Like the old VBA-based Excel software (V2.8.4), the web version (V3.0) also provides a number of options for calculating thermowells. For example, all shank designs within the scope of ASME PTC 19.3 TW-2016 (tapered, straight or stepped) can be calculated in combination with any type of process connection (flanged or threaded, welded or Vanstone). Inputs are possible in either metric or imperial units or in a mixture of the two. Also, the full version of the program currently lists 55 materials with stored data in accordance with ASME BPVC Section II Part D, and more can be added if required. The materials can be selected using their ASTM designation or alternatively their UNS number, their DIN number or their standard international designation.

Like its Excel predecessor, the online program also integrates help information which displays using a mouseover function. Explanatory texts and detailed descriptions of all software features are included. In addition, any input values that are outside the PTC 19.3 design specifications appear on a coloured background. In the event of a failed thermowell calculation, the familiar “note code” and the recommended “optimised insertion length” make it a simple matter to modify the design, so that it meets the specifications at the second attempt.

Summary

Wika’s thermowell calculation program conforming to the globally recognised ASME PTC 19.3 TW-2016 standard has now gone online with Version 3.0. The new web solution is divided into two parts: on the one hand, there is a freely available version with functionality limited to the essentials for calculating a single thermowell (single calculation). On the other hand, a full version requiring registration and verification exists that enables simultaneous calculations of any number of thermowells (multiple calculation). The input values can be called up and edited at any time. Azure Active Directory B2C protects all data from unauthorised access. Results can be stored locally thanks to the Excel and / or PDF export functions.

Regular updates will be released for the web-based software. A calculation for fabricated thermowells according to DIN 43772 (Supplement 2), a stress calculation for thermowells in ScrutonWell design as well as a graph of the calculation environment are just some of the features that could be integrated in the future.

Author: Kai Grabenauer, Product Manager, CoE Europe Electrical Temperature Measurement, WIKA Alexander Wiegand SE & Co KG

Text Source: Wika

Picture Source: Gorodenkoff – stock.adobe.de/Wika