Available

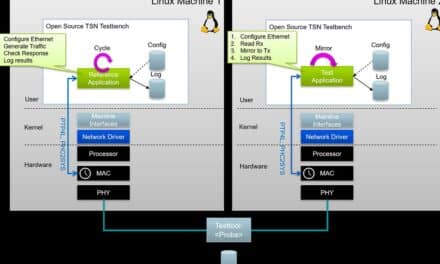

TSN Testbench

The introduction of Preempt_rt into the Linux kernel along with a multitude of enhancements to other kernel and user space subsystems, including the communications stack, has made it possible to support such mixed criticality workloads on a standard Linux kernel-based operating system.